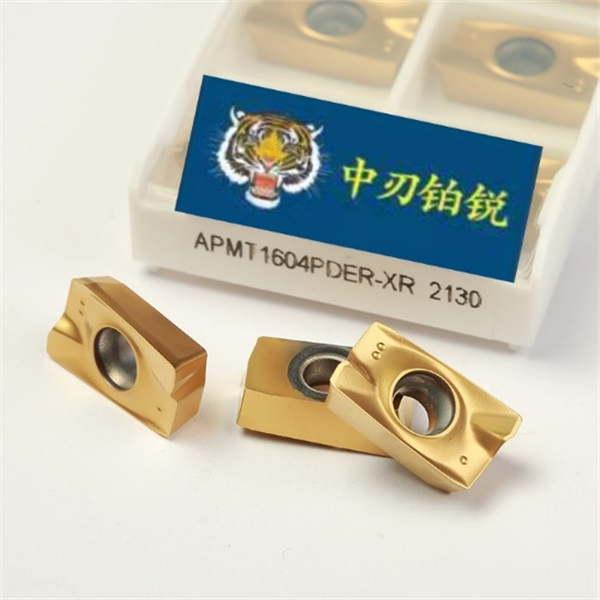

Thawj Durable APMT cnc inserts hom rau milling APMT1604PDER DP5320 Cov khoom siv ncaj qha los ntawm cov chaw tsim khoom

Product Description

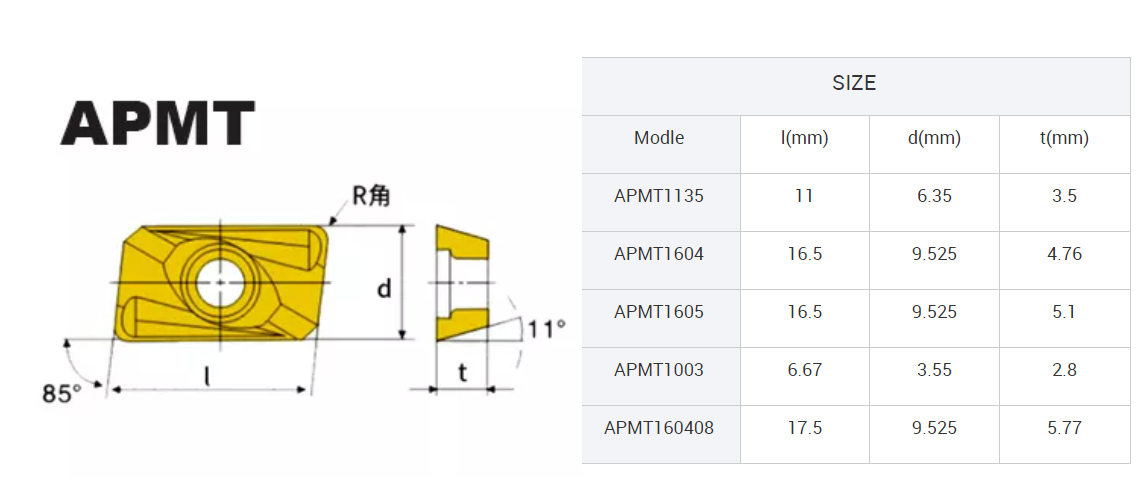

Carbide APMT PVD Coated inserts feem ntau yog siv rau indexable square xub pwg kawg milling cutters thiab lub ntsej muag milling cutters.APMT inserts yog nrog precision-molded IC, zoo molded nti breaker.Lawv muaj qhov ntse thiab honed txiav ntug thiab 11 ° nyem lub kaum sab xis.Lawv yog cov ntsia hlau qhov tsim raws li ISO.Feem ntau, nws yog saib raws li nrog 2 txiav ntug.Txawm li cas los xij, lawv yeej muaj 4 txiav ntug.Thaum lawv tau nruab rau ntawm 90 ° indexable milling cutters thiab ob lub npoo ua npub, lawv tuaj yeem ntsia tau rau ntawm 75 ° indexable milling cutters  thiab txuas ntxiv rau lwm daim ntawv thov milling nrog rau ob sab.APMT yuav yog qhov kev xaiv zoo rau cov neeg siv kawg, vim nws tuaj yeem txhim kho cov khoom tsim tau zoo.

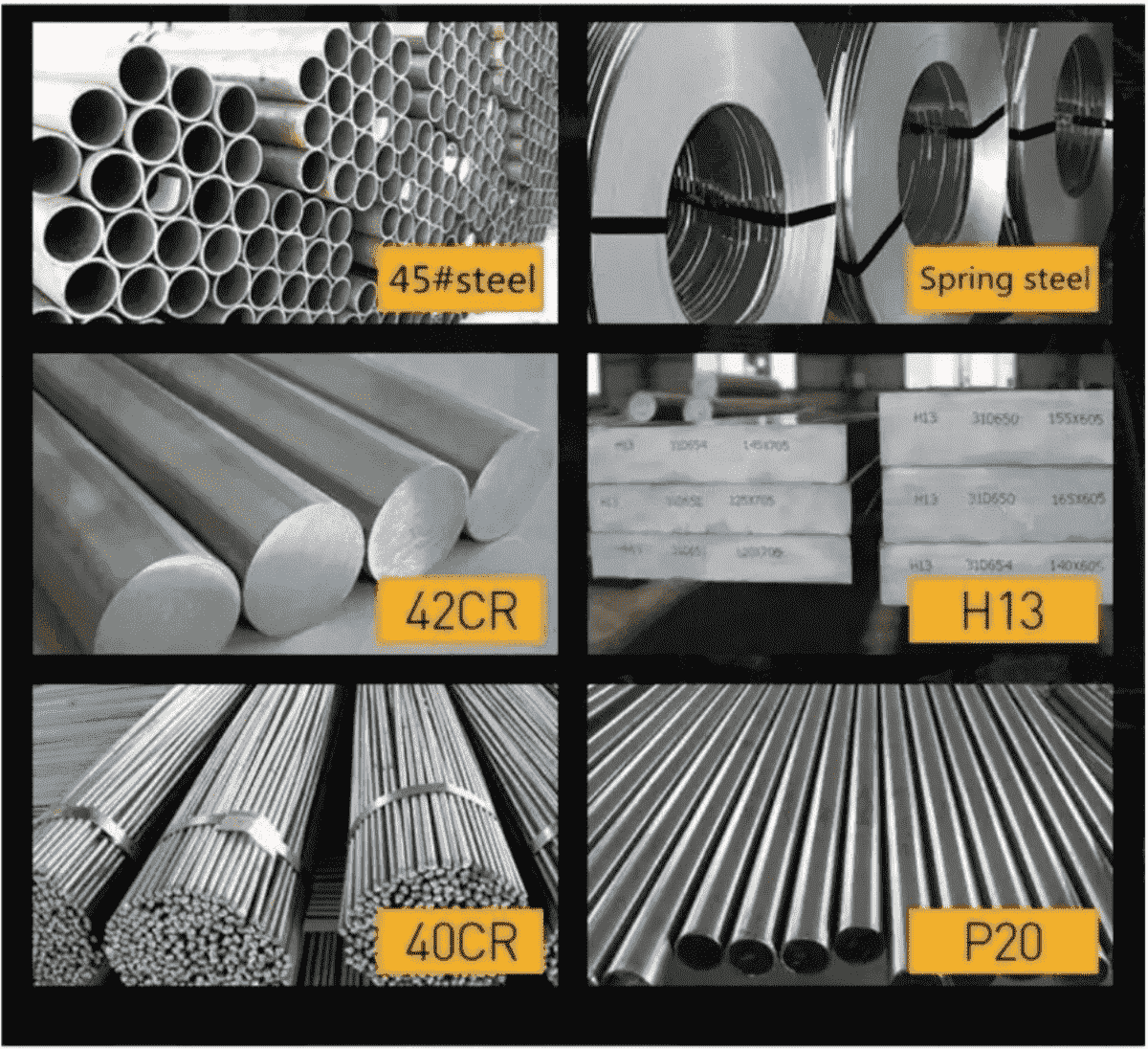

Daim ntawv thov tseem ceeb

Rau kev ua cov pa roj carbon steel, cam khwb cia hlau, stainless hlau

Kev lag luam ntawm daim ntawv thov

CNC tig thiab milling tungsten carbide cov cuab yeej khoom siv tau dav siv nyob rau hauv: Automotive manufacturing kev lag luam, Mould manufacturing kev lag luam, Aviation kev lag luam, kev lag luam kws muaj txuj ci, kev lag luam hnyav thiab ntau lwm yam teb.

peb tuaj yeem tsim ntau hom tungsten carbide txiav cov cuab yeej ntxig raws li cov duab kos sib txawv.

peb tuaj yeem muab tag nrho cov kev txhawb nqa kev daws teeb meem rau machining teb.

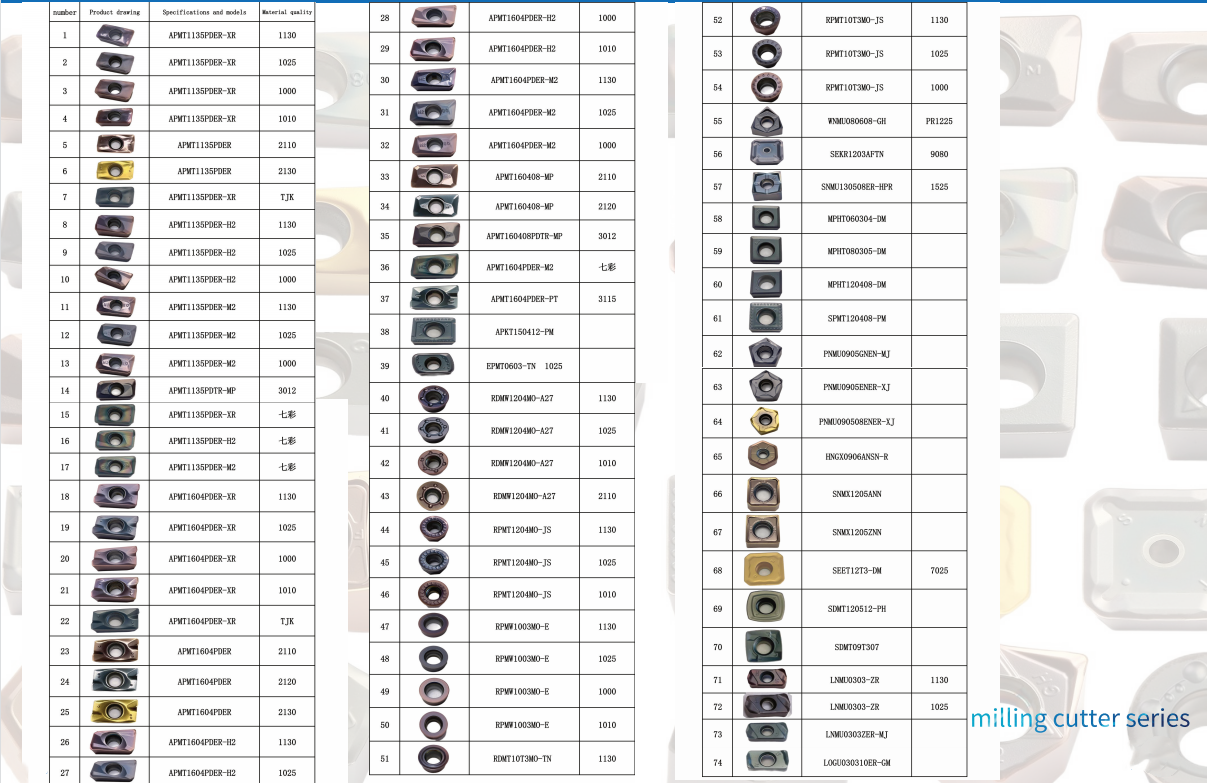

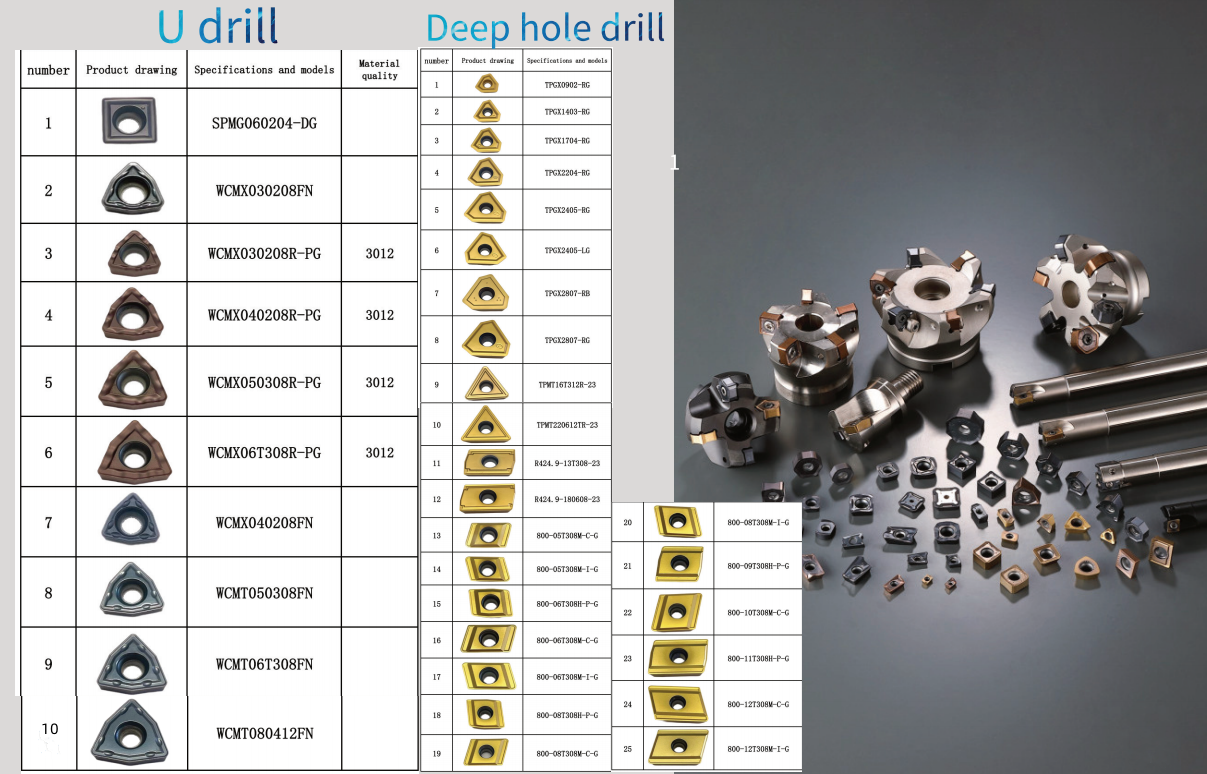

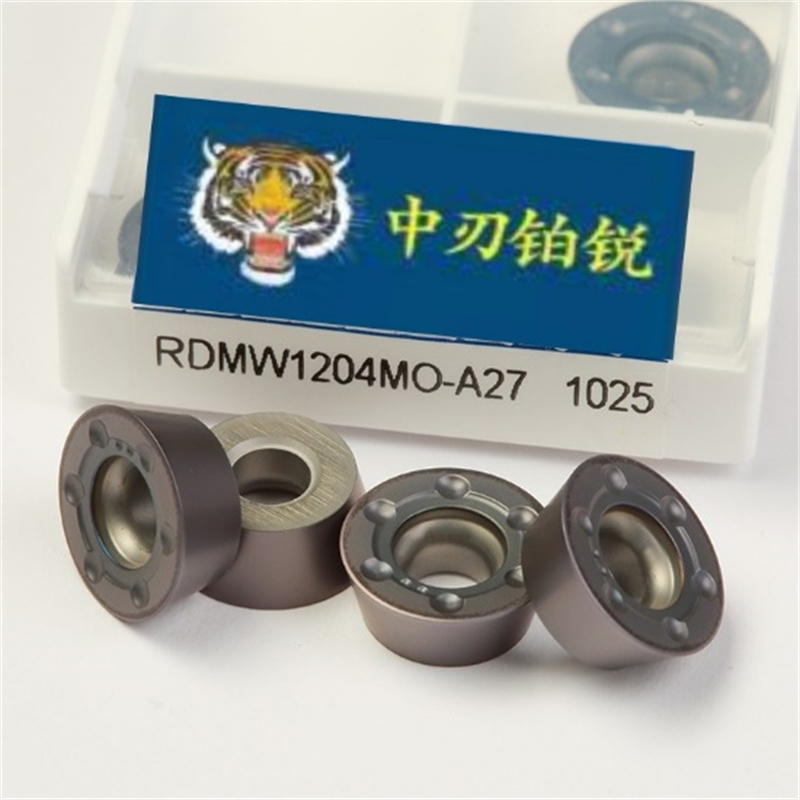

Khoom Specifications

Cov khoom siv ntau lawm

QC cov khoom siv

Daim ntawv pov thawj

Qhov zoo

1. Zoo hnav tsis kam, siab dabtsi yog khoov lub zog, muaj zog bonding kuj, zoo heev kub kuj, cuam tshuam toughness thiab siab hardness.

2. Lub neej ua haujlwm ntev thiab yooj yim rau kev sib dhos, tsis muaj tawg lossis chipping

3.Specification thiab raug ntawm peb CNC inserts hom yog tag nrho ua raws li ISO tus qauv.

Nta

1. Zoo heev hnav tsis kam, zoo kub hardness, txhim kho ntau lawm efficiency.

2. Precision av thiab polished, zoo meej txiav nyhuv

3. PVD txheej ua kom lub neej ntev dua.

4. tuaj yeem phim feem ntau ntawm cov khoom lag luam bar / tuav.