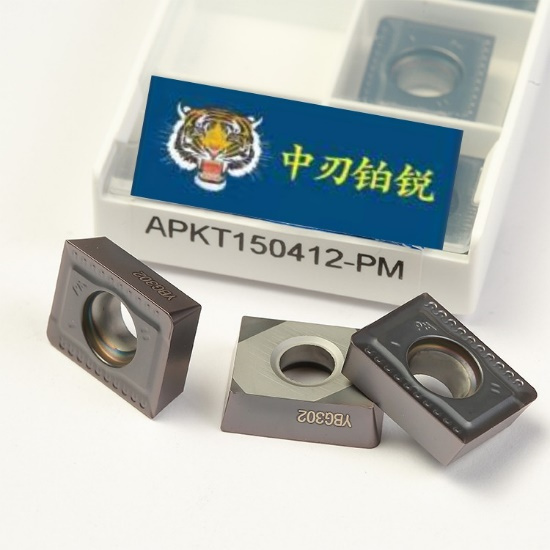

Tungsten Carbide Tig Indexable Insert APMT1135 rau amuninum / stainless hlau / Cam khwb cia hlau

Cov ntaub ntawv yooj yim

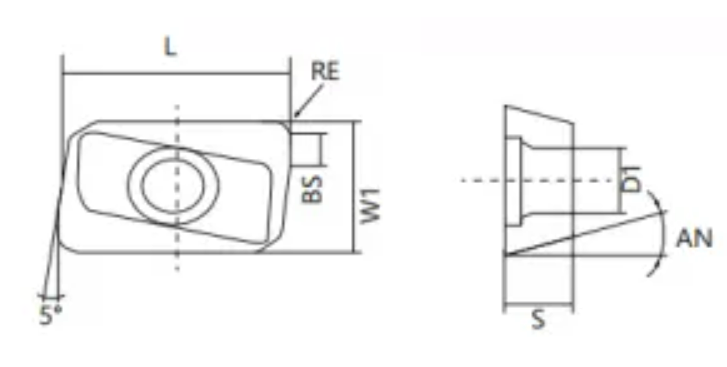

APMT1135 yog nyob rau hauv lub xub pwg nyom milling, uas tsim ob lub ntsej muag tib lub sijhawm, uas yuav tsum muaj kev sib xyaw ntawm peripheral milling thiab lub ntsej muag milling.Lub xub pwg nyom mills ntawm cov qauv tsim feem ntau muaj peev xwm milling "tseeb", 90-degree lub xub pwg nyom.Ntau lub xub pwg ntsej muag mills yog universal cutters, thiab tuaj yeem siv tau zoo rau kev ua qhov.Lub xub pwg milling tuaj yeem ua tiav nrog lub xub pwg nyom milling cutters, kawg mills, ntev ntug milling cutters, sab milling cutters thiab lub ntsej muag milling cutters kuj siv tau.

Main Application:

Rau kev ua cov pa roj carbon steel, cam khwb cia hlau, stainless hlau

Kev lag luam ntawm kev siv:

CNC tig thiab milling tungsten carbide cov cuab yeej khoom siv tau dav siv nyob rau hauv: Automotive manufacturing kev lag luam, Mould manufacturing kev lag luam, Aviation kev lag luam, kev lag luam kws muaj txuj ci, kev lag luam hnyav thiab ntau lwm yam teb.

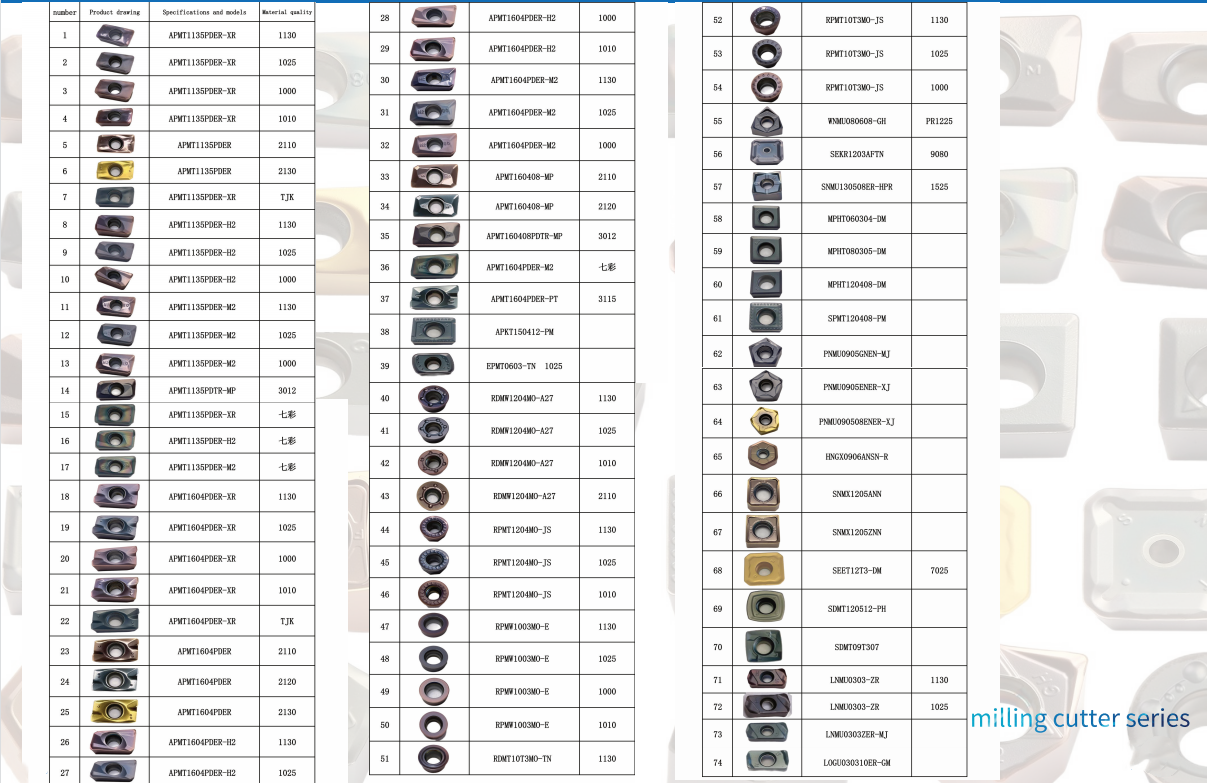

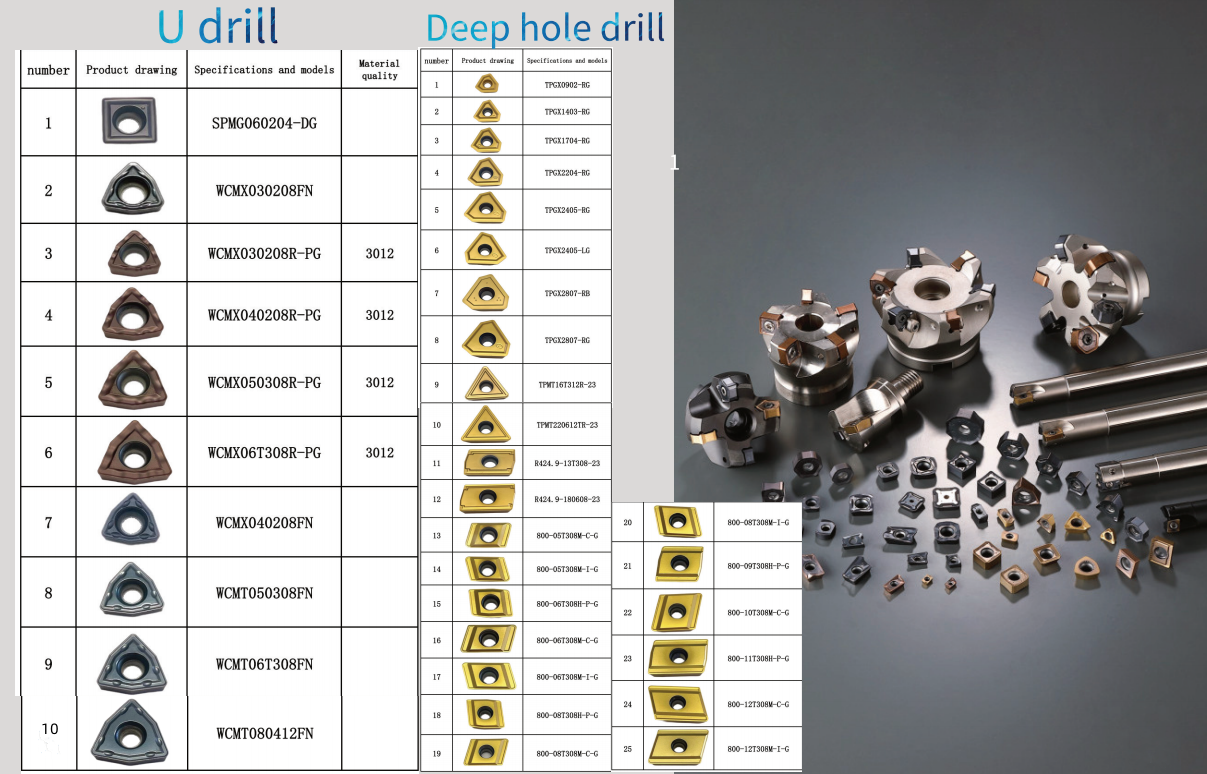

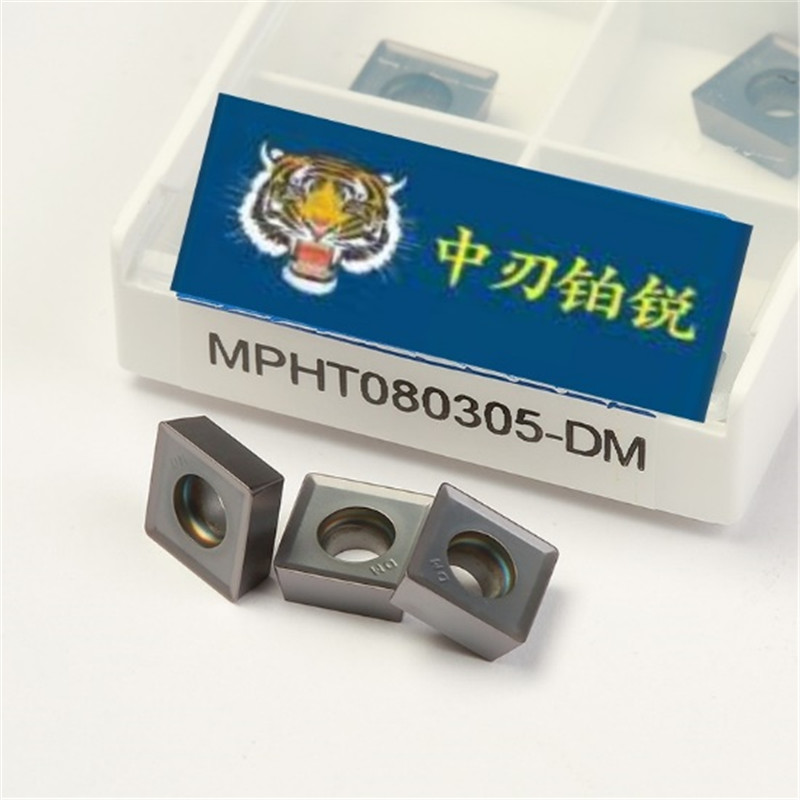

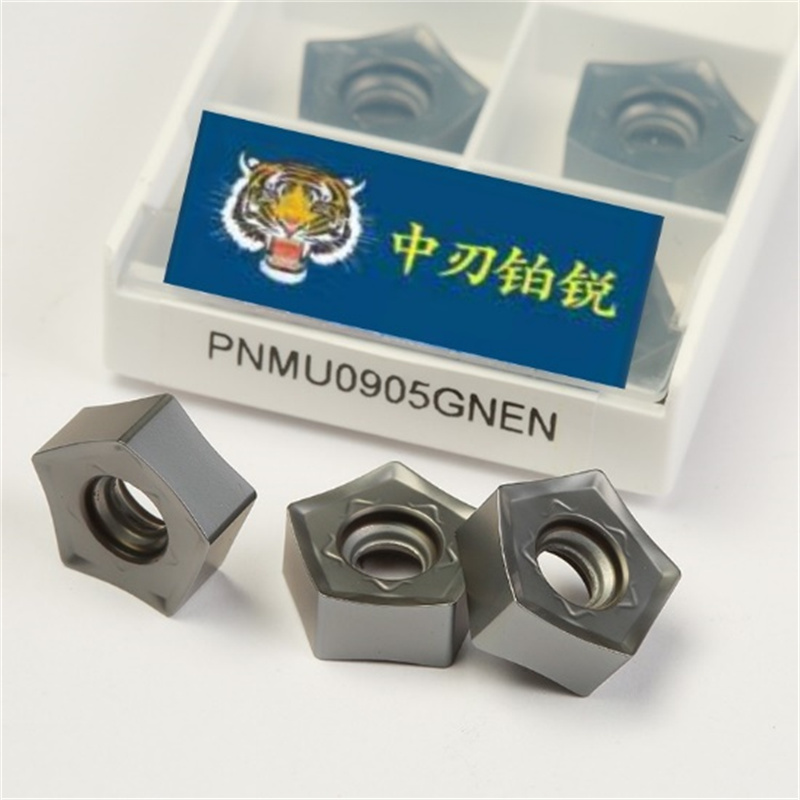

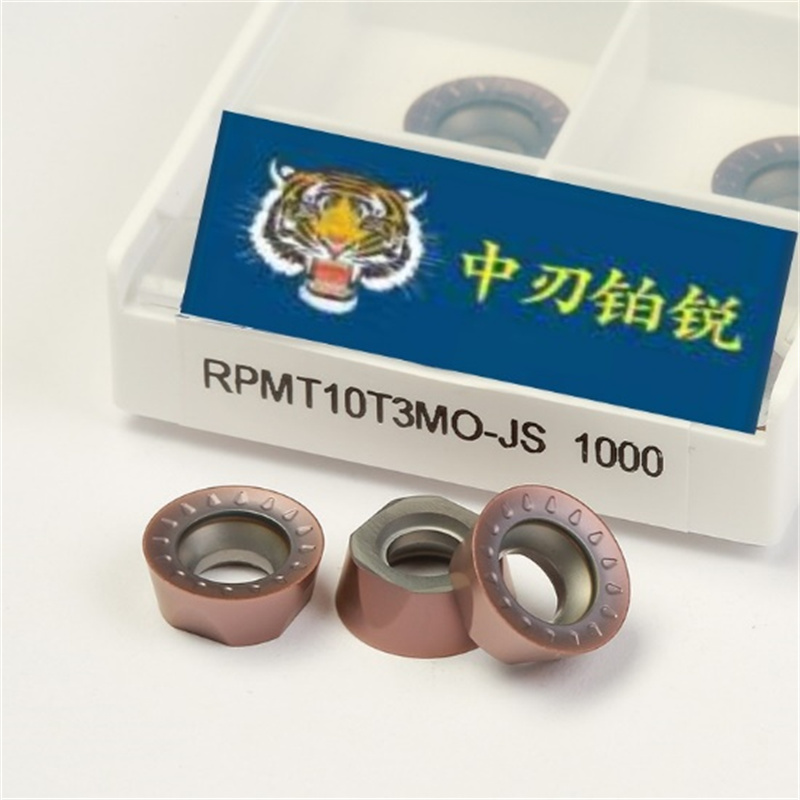

peb tuaj yeem tsim ntau hom tungsten carbide txiav cov cuab yeej ntxig raws li cov duab kos sib txawv.

peb tuaj yeem muab tag nrho cov kev txhawb nqa kev daws teeb meem rau machining teb.

Cov khoom siv ntau lawm

QC cov khoom siv

Daim ntawv pov thawj

Qhov zoo

1. Kev daws teeb meem zoo txhim kho ntug ua haujlwm hardening thiab lwm yam teeb meem machining.

2. Txiav ntug inclination designation yog qhov zoo los tswj cov nti ntws cov kev taw qhia thiab tau txais qhov zoo tshaj plaws nto.

3. ntse txiav ntug, me txiav quab yuam.

4. Zoo machining nto zoo.

5. Tshwj xeeb nti breaker tsim kom txiav ntug ntse thiab nyab xeeb.

6. Zoo tiv thaiv kev cuam tshuam.

7. Cov cuab yeej zoo heev lub sijhawm.

Nta

1. tshwj xeeb nto kho nrog txheej.

2.suit rau high precision ua.

3. Kev xa khoom sai thiab kev pabcuam zoo tshaj plaws.

4. Zoo siab nrog tus nqi sib tw.

5. Dav siv nyob rau hauv kev lag luam ntawm metalworking machinery

6. High precision, hloov tau yooj yim, siv dav.